Exploring the Benefits of Personalized Injection Molding

Bespoke molding technique is a fabrication method that enables the design of precise and intricate plastic components tailored to specific needs. This advanced method has transformed the way products are designed and produced, offering a superb mix of efficiency and adaptability. With the ability to produce high volumes of components rapidly and correctly, custom injection molding is regarded as a popular choice for firms in various industries.

What causes custom injection molding especially appealing is its versatility. It allows for various substances, permitting manufacturers to choose the best type of plastic for their uses. This flexibility not only improves the performance of the final product but also facilitates cost efficiency. By grasping the core advantages of custom injection molding, manufacturers can capitalize on this technology to improve their production methods and eventually meet their market demands more efficiently.

Cost-Effectiveness

Custom injection molding|Custom molding offers considerable cost-effectiveness relative to different production techniques. The initial setup costs can be expensive because of the need for specialized molds; but, once these molds are created, they can produce large quantities of parts swiftly and reliably. This increased production rate reduces the cost for each part, making it a budget-friendly solution for manufacturers seeking to create large volumes of components.

Another factor contributing to cost efficiency is the decrease of scrap. Custom injection molding allows for accurate management over the quantity of material utilized in each production cycle. This exactness reduces scrap and guarantees that resources are used efficiently. Manufacturers can also choose tailored materials that meet their needs without over-spending on unnecessary material.

Additionally, custom injection molding leads to reduced labor expenses. The mechanization inherent in the injection molding process reduces the need for extensive manual labor. With machines handling the lion's share of production, companies can distribute their workforce more effectively, leading to lower overhead costs and enhanced efficiency.

Design Versatility

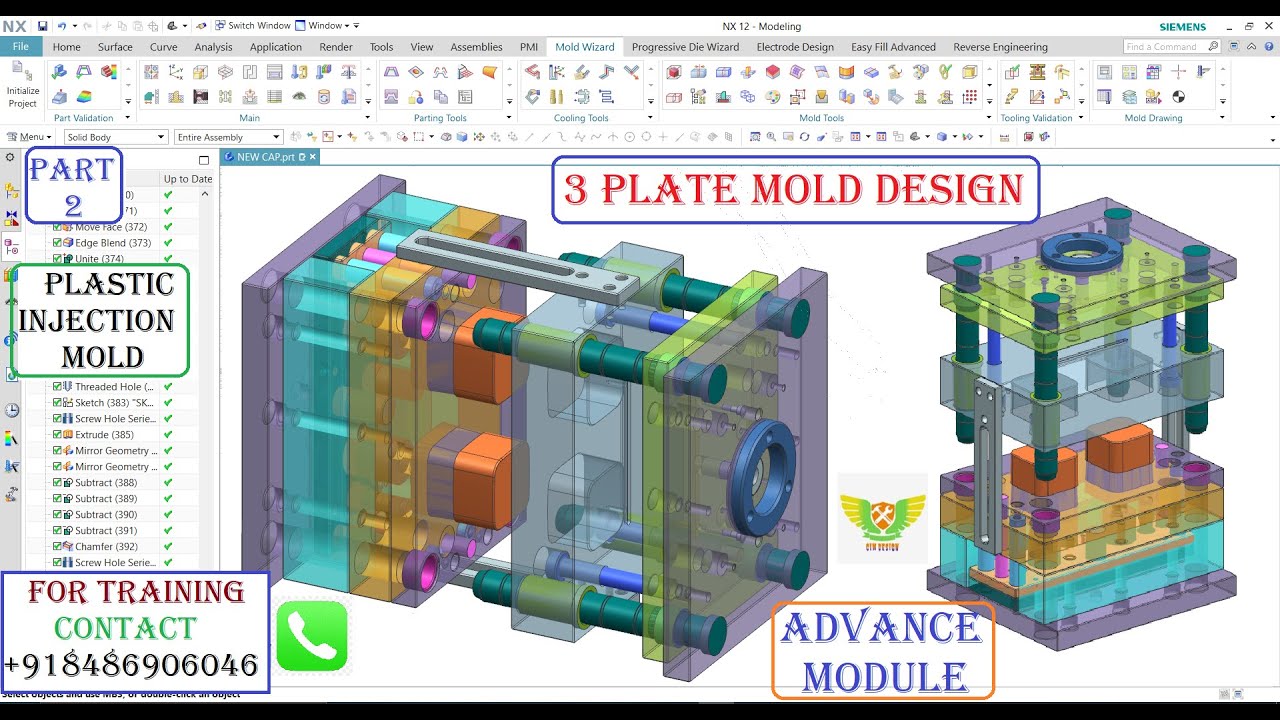

Tailored injection moulding offers exceptional design versatility, enabling producers to craft intricate formulations and complex geometries that are hard or impossible to achieve using different production methods. With advanced computer-aided design software, engineers can create prototypes that completely represent the final product. This capability ensures that every detail is considered, allowing the production of parts that satisfy specific dimensional and functional needs.

Another aspect of architectural versatility is the ability to select from a variety of materials. Custom injection moulding allows for different polymer materials, composite materials, and other materials, each with distinct characteristics suited to specific applications. This versatility enables manufacturers to enhance their products for efficiency, longevity, and aesthetic appeal. Designers can tailor the material selection to the specific use, whether it be lightweight components for retail products or robust solutions for manufacturing applications.

In addition, custom injection molding allows for modifications throughout the design process. Adjustments can be made based on input or test data without incurring significant holdups or expenses. This continuous methodology promotes innovation, as companies can refine their designs in actual time, adjusting to market demands and customer preferences. This degree of flexibility is a key advantage in a challenging landscape, where the ability to react swiftly can be crucial.

Quality and Accuracy

Custom injection molding is famous for its ability to produce premium parts with remarkable precision. This manufacturing process allows for tight tolerances that are often required in industries such as aviation, vehicle, and electronics. By utilizing advanced mold design and modern machinery, manufacturers can achieve dimensional accuracy that meet the specific needs of their projects. This level of precision ensures that parts fit together seamlessly, reducing the risk of defects and enhancing the overall functionality of the final product.

One of the main advantages of custom injection molding is the consistency it offers. Once a mold is created, it can produce countless of identical parts without notable variation. This repeated accuracy is essential for businesses looking to maintain strict quality standards of quality throughout their production runs. Additionally, because the process allows for precise control and control of the flow of materials and heat, manufacturers can mitigate the risk of defects caused by variations in the injection process itself.

Furthermore, the selection of materials in custom injection molding contributes substantially to the quality and durability of the parts produced. With a wide range of thermoplastics and thermosetting polymers available, businesses can choose materials that not only meet their design requirements but also provide the necessary robustness and resistance to external conditions. This versatility in material selection, combined with the precision of the molding process, results in components that are resilient, trustworthy, and customized to the specific demands of their applications.